A traditional and widely used vibrating screen, mostly used for medium and fine particle screening. 【Processing capacity】: 20~300t/h 【Scope of application】: Xinhai vibrating screening machine is suitable for classifying medium and fine particle size in mining, coal, metallurgy, building materials, chemical and other departments.

Xinhai vibrating screen equipment has large amplitude and high screening efficiency;

Wear-resistant rubber screen can be provided, the service life is 10-20 times that of steel, and 4-6 times that of polyurethane;

Can provide high elastic wear-resistant rubber spring, long life, low noise, easy maintenance; provide two types of vibrating screen: seat type and hanging type;

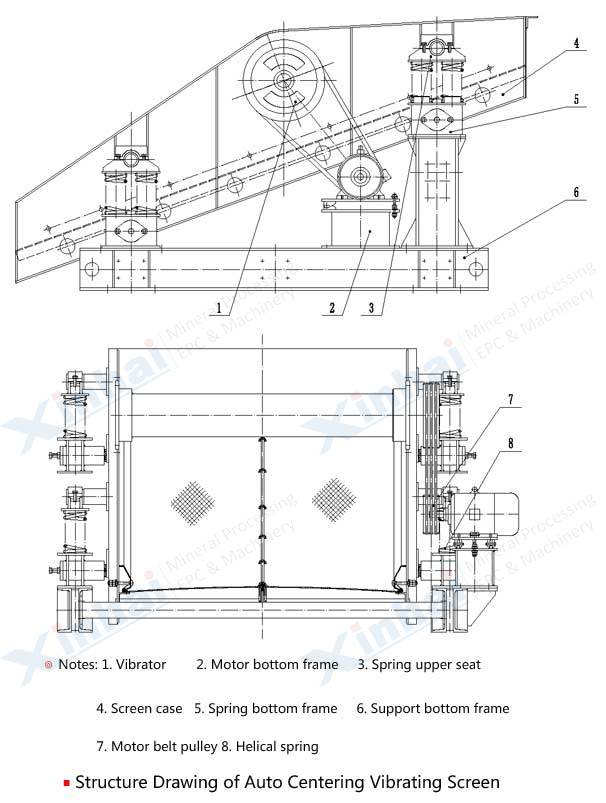

The large pulley and the eccentric shaft have an eccentricity of 3-5mm, which balances the overall movement of the large pulley when the vibrating screen vibrates and increases the stability of the transmission;

The material on the screen of the self-centering vibrating screen can achieve good loosening and stratification under the action of vibration;

The weight of the vibrating screen can be adjusted, and the amplitude of the screen can be adjusted according to production requirements;

When the amount of ore feeding changes, the amplitude also changes. When the amount of ore is small, the amplitude increases and the vibration intensifies, and when the amount of ore is large, the amplitude decreases. Changes in the amount of ore feeding will affect the "dynamic balance", which will cause some vibrations in the center of the pulley;

It is suitable for medium and fine particle screening but not suitable for coarse material screening.

Driven by the motor through the pulley, the eccentric main shaft integrated with the screen box rotates and generates centrifugal force, and drives the vibration of circular trail of the screen box.

| Model | Spec. | Max. Feed Size (mm) | Capacity (t/h) | Motor Model | Motor Power (kW) | Weight (kg) | Remarks |

| SZZ0918 | 900 X1800 | 40 | 20 ~25 | Y100L1-4 | 2.2 | 420 | Hanged |

| SZZ0918 | 10 ~30 | 553 | Pedestal | ||||

| 2SZZ0918 | 20 ~40 | 570 | Pedestal | ||||

| SZZ1225 | 1250X2500 | 100 | 100 | Y132S-4 | 5.5 | 1017 | Hanged |

| SZZ1225 | 100 | 1466 | Pedestal | ||||

| 2SZZ1225 | 100~150 | 1320 | Hanged | ||||

| 2SZZ1225 | 100~150 | 1870 | Pedestal | ||||

| SZZ1530 | 1500X3000 | 90~200 | Y132M-4 | 7.5 | 1850 | Hanged | |

| SZZ1530 | 2665 | Pedestal | |||||

| 2SZZ1530 | 2963 | Hanged | |||||

| SZZ1540 | 1500X4000 | 100 | 90~200 | Y160L-4 | 15 | 2865 | Pedestal |

| 2SZZ1540 | 1500X4000 | 400 | 90~200 | Y160L-4 | 15 | 3412 | Pedestal |

| SZZ1836 | 1800X3600 | 150 | 100~300 | Y160M-4 | 11 | 4500 | Hanged |

| 2SZZ1836 | Y180M-4 | 18.5 | 5616 | Pedestal |

In a mineral processing plant in Yunnan, the material has a large water content, the equipment is seriously damaged, and the production cannot be carried out, so the washing facilities are added, and the washing and desliming are carried out before fine crushing. The custom central vibrating screen used by Xinhai screening machine manufacturers will generate a large centrifugal force due to the eccentric shaft, and at the same time, it can be lined with wet wear-resistant rubber to increase the service life of the equipment, and two additional sets are used for desliming. The ore is washed and deslimed in two stages of the vibrating screen, and the screening efficiency is improved, which greatly ensures the normal operation of the pre-selection work and reduces the production cost.