If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

South Africa's sulfide nickel deposits hold immense potential, yet developers face five persistent nickel recovery barriers:

1. Unpredictable Ore Grades disrupting stable nickel recovery rates

2. Complex Metal Associations causing 18-22% nickel losses in tailings

3. Legacy Equipment wasting 35% energy on inefficient nickel liberation

4. EPCM Fragmentation delaying nickel recovery optimization by 6-9 months

5. Tailings Constraints forcing suboptimal nickel flotation strategies

The Recovery Gap

While the SA Mining Council reports 65-75% average nickel recovery, our smart plants achieve:

✓ 85%+ nickel recovery through adaptive control

✓ <1.8% Ni in tailings via real-time XRD adjustments

✓ 15% lower kWh per ton of recovered nickel

Our ISO-certified solutions have reclaimed over 920,000 tons of nickel equivalents through:

- Zimbabwe Lithium Project: 82% nickel recovery from pegmatite tailings

- Guinea Gold Plant: 11.3g/t nickel byproduct recovery via CIP optimization

- Morocco Silver Operation: 14% nickel recovery boost using MQGg Ball Mills

Stage 1: Selective Crushing → Maximize Nickel Liberation

Our HPGR System enhances nickel recovery by:

✓ Maintaining 12-15mm optimal particle size for grinding

✓ Reducing slimes generation by 40% (critical for sulfide surface exposure)

Stage 2: Energy-Efficient Grinding → Unlock Nickel Sulfides

MQGg Ball Mills improve nickel recovery economics through:

✓ 20% lower energy per recovered nickel unit

✓ 0.074mm grind size precision (±5% variance)

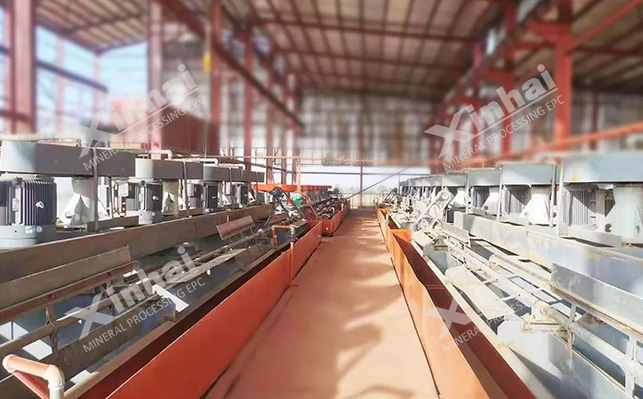

Stage 3: Smart Flotation → Capture Elusive Nickel Particles

Our Advanced Flotation Technology achieves 92-94% nickel recovery in PGMs-rich ores via:

✓ Potential control (-28mV to -32mV) for optimal pentlandite adhesion

✓ Coarse particle recovery (0.3-0.5mm) without grade compromise

Stage 4: Water-Neutral Dewatering → Secure Nickel Margins

XMAZ Filters protect nickel recovery profits by:

✓ Recovering 2.1-3.8% nickel from recycled process water

✓ Ensuring NEMA-compliant tailings with 14.7% moisture

Dynamic Optimization

- Live XRD Analysis: Adjusts nickel recovery parameters every 15 minutes

- Digital Twin Modeling: Predicts nickel recovery impacts of ore variations

Cost-Per-Recovered-Nickel™ Model

Our modular plants reduce nickel recovery costs by:

✓ 30% lower CAPEX per annual nickel ton

✓ 22% less reagents through smart dosing

Scalable Recovery Solutions

From 10tpd pilot nickel recovery to 5,000tpd megaprojects, we guarantee:

✓ ±2% nickel recovery rate consistency

✓ 48-hour emergency spares delivery

Contractual Nickel Recovery Assurance

We stake our reputation on:

✓ ≥85% nickel recovery or penalty payments

✓ 100% NEMA compliance with insurance-backed warranties

Ready to Redefine Your Nickel Recovery Economics? Contact Me:WhatsApp-0086 1381 1510 145