If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Flotation machines are vital tools in the mining world. They help pull valuable minerals out of rocky waste using air bubbles and special chemicals. These machines boost how much mineral you recover, improve the quality of the final product, and cut down on costs. Over the years, flotation tech has grown smarter, tackling the needs of huge mining sites and trickier ores.

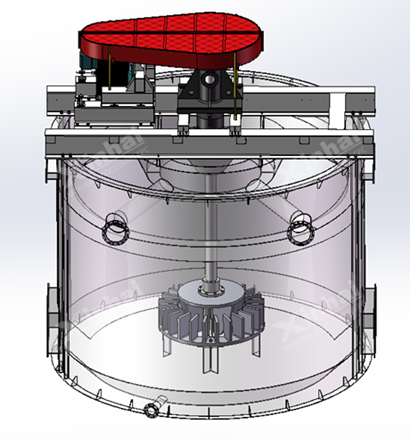

A Circular Flotation Machine stands out with its round tank and central mechanism. Unlike the usual boxy designs, this round shape creates smooth, even flow inside the tank. It cuts down on spots where slurry just sits, improves how air spreads, and keeps froth steady. For example, Xinhai’s Large Circular Flotation Machine uses a clever tank setup to make slurry flow easily, spread air evenly, and collect froth without hassle. Honestly, it feels like a game-changer when you see how smoothly it runs compared to older models.

Older flotation machines often have rectangular or square tanks with impellers stuck on the sides. These setups can cause problems like sand piling up in corners or uneven wear on parts. Air doesn’t always mix well, which hurts performance. Plus, their boxy shape makes it tough to scale up for big operations or fit into tight spaces. Many older models also rely on workers manually tweaking settings, which can feel like a step back when you compare it to today’s smarter systems.

| Aspect | Circular Flotation Machine | Traditional Flotation Machine |

|---|---|---|

| Tank Shape | Round, central mechanism, smooth flow | Rectangular, uneven flow, dead zones |

| Air Distribution | Uniform bubbles, higher recovery | Uneven mixing, lower recovery |

| Wear & Maintenance | Even stress, durable, low upkeep | Uneven wear, frequent repairs |

| Energy Use | Efficient, saves up to 15% | Higher consumption |

| Space Use | Compact, saves ~25% area | Bulky, needs more space |

| Automation | Smart controls, easy operation | Manual adjustment |

| Overall | High efficiency, modern, sustainable | Lower efficiency, outdated design |

Circular Flotation Machines bring a fresh approach to design. The round tank spreads stress evenly, so parts don’t wear out as fast. Slurry moves in a consistent, predictable way, unlike the choppy flow in rectangular tanks.

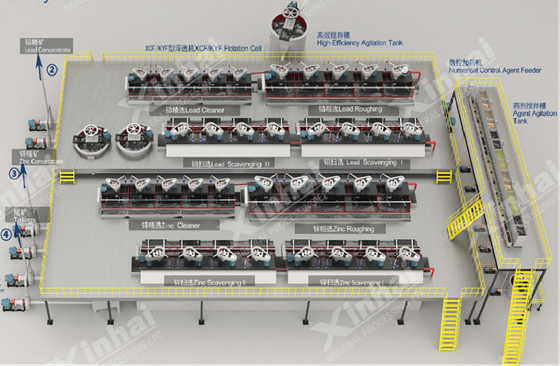

Xinhai’s KYF series Large Circular Flotation Machine, for instance, has a revamped tank, upgraded drive systems, and tougher components. They’ve also improved how it’s built and installed, plus added smart controls. These changes make the machine run smoothly and last longer. In a copper mine I heard about in Chile, switching to circular designs cut mechanical failures by nearly 30%—that’s a big deal for keeping things running.

The round shape avoids sand buildup, a headache in older designs. Rectangular tanks often get clogged in corners, forcing workers to stop and clean them. Circular tanks, though, keep things moving naturally. The impeller in Xinhai’s design sits centrally, stirring slurry evenly without creating chaotic currents. This setup feels more reliable, especially for big operations crunching thousands of tons of ore daily.

When it comes to results, Circular Flotation Machines shine. They pull out more minerals and produce better froth thanks to even air distribution and stable flow. In a gold processing plant in Australia, for example, a circular machine boosted recovery rates by 5% compared to older rectangular models. The smooth mixing cuts down on turbulence, which means fewer bubbles collapse before they carry minerals to the surface. This leads to steady, predictable output—something every plant manager wants.

Xinhai’s KYF series tackles issues like sand piles and uneven stress head-on. Its design ensures air bubbles spread uniformly, so more mineral particles stick to them. Data from a zinc mine showed a 10% jump in concentrate grade after switching to a circular model. Less turbulence also means operators don’t have to fiddle with settings as much, saving time and effort.

Circular Flotation Machines are built tough for rough mining conditions. Xinhai’s Large Circular Flotation Machine uses heavy-duty parts designed to handle gritty, abrasive slurries. In a South African mine, these machines ran for over a year with barely any repairs, compared to older models needing fixes every few months. That kind of durability means less downtime and lower repair bills.

Xinhai also uses precise manufacturing tools to ensure every part fits perfectly. Sloppy machining or shaky installations, common with older designs, are no longer an issue. For instance, a nickel plant reported 20% lower maintenance costs after upgrading to Xinhai’s circular machines. The smart design and sturdy build keep things running smoothly, which saves money in the long run. Honestly, it’s impressive how much thought went into making these machines low-maintenance.

Circular Flotation Machines are kinder to the environment. They use energy more efficiently and waste less material. Xinhai’s Large Circular Flotation Machine, with its smart tank and tough components, cuts energy use by up to 15% in some cases, like a copper mine in Peru. Its compact, round shape also fits better in crowded plants. For a new mine setup in Canada, the circular design saved 25% of the floor space compared to rectangular tanks, leaving room for other equipment.

The smooth flow and better froth collection mean less chemical reagent gets wasted. This not only saves money but also reduces the environmental footprint. Mines face strict rules on waste these days, so this is a big plus. The easy setup also means less construction mess when installing new machines or upgrading old ones.

Modern Circular Flotation Machines come with smart tech that makes them easier to run. Xinhai’s Large Circular Flotation Machine, for example, has controls that track things like air flow, slurry level, and froth thickness in real time. In a lead mine in Mexico, operators used these controls to tweak settings on the fly, boosting recovery by 8%. No more guessing or manual adjustments—just data-driven decisions.

These systems also automate routine tasks, so workers can focus on bigger issues. The tech isn’t just fancy; it’s practical. For instance, sensors catch problems early, like a slight drop in air flow, before they mess up production. This kind of intelligence is becoming a must-have as mines aim to do more with less.

The mining world is shifting toward greener, more efficient equipment. Circular Flotation Machines fit right into this trend. As mines get bigger and ores get tougher to process, companies want machines that deliver high output with low impact. Xinhai’s designs are gaining traction because they solve real problems—like low recovery or high energy costs. A recent survey showed 60% of large-scale mines are either using or considering circular machines within the next five years.

Manufacturers like Xinhai lead the charge by building equipment for huge operations. Their Large Circular Flotation Machine handles the demands of massive plants while keeping things simple and sustainable. It’s no surprise that mines in places like Australia and South America are switching over fast.

Choosing the right flotation machine depends on a few key things. First, think about the ore—what minerals are you pulling out, and how tough is it to process? Plant layout matters too; circular machines save space, which is great for tight setups. Automation is another factor—smart controls can make life easier, especially in big operations. Don’t forget maintenance; machines like Xinhai’s KYF series need less upkeep, which saves headaches down the road.

Energy use and environmental rules are also big deals. Circular designs often sip less power and waste fewer chemicals, which helps meet strict regulations. For a mine in Mongolia, switching to circular machines cut energy costs by 12% while meeting new environmental standards. If your plant needs high output, easy upkeep, and a smaller footprint, a Circular Flotation Machine is worth a look. It’s built for today’s demands and ready for tomorrow’s challenges.

In short, Circular Flotation Machines like Xinhai’s KYF series bring smarter design, better performance, and lower costs to the table. They tackle the flaws of older rectangular models while fitting the needs of modern, sustainable mining. Whether you’re running a massive copper mine or a small gold plant, these machines offer a solid, future-proof choice.