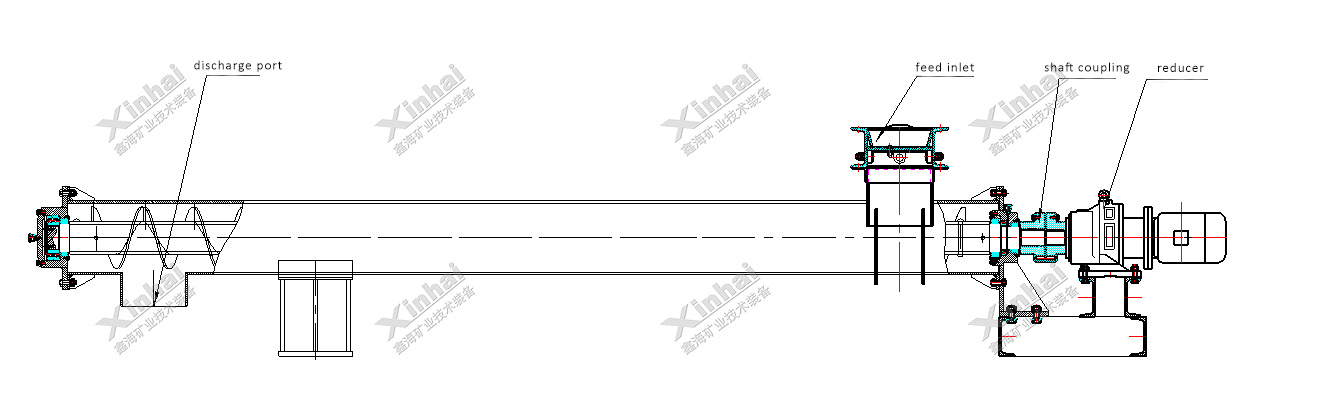

A conveying device that uses a driving device to drive the screw to rotate and push the material to achieve the purpose of conveying. 【Processing capacity】: 3-139 t/h 【Scope of application】: The screw conveyor is mainly used for conveying powdery, granular and small block materials, such as mineral powder, coal powder, soda ash, reclaimed rubber powder, zinc oxide, calcium carbonate and small lump coal, etc. and brittle materials.

Simple structure and small cross-sectional size;

Good sealing, reliable work, convenient for intermediate loading and unloading;

The conveying direction can be reversed, and it can also be conveyed in opposite directions at the same time;

During the conveying process, the materials can be stirred, mixed, heated and cooled;

The material flow can be adjusted through the loading and unloading gate;

The unit power is large, and the sealing of the trough and the proper clearance between the screw and the shell should be maintained during use.

The screw conveyor is composed of the closed tank box and screw. The material in the tank body is pushed out by the screw rotation. The weight of the material and the friction resistance of the chassis to the material make the material not rotate with the blade of the screw conveyor.

| Screw dia (mm) | Conveying temperature (℃) | Installation angle | Coal fines | Soda | Cement | |||

| Maximum revolution of the screw axis(rpm) | Maximum throughput(tph) | Maximum revolution of the screw axis(rpm) | Maximum throughput(tph) | Maximum revolution of the screw axis(rpm) | Maximum throughput(tph) | |||

| GX150 | ≤200 | ≤20° | 190 | 4.5 | 120 | 3 | 90 | 4.1 |

| GX200 | 150 | 8.5 | 120 | 6.7 | 75 | 7.9 | ||

| GX250 | 150 | 16.5 | 90 | 10.7 | 75 | 15.6 | ||

| GX300 | 120 | 23.3 | 90 | 17.7 | 60 | 21.2 | ||

| GX400 | 120 | 54 | 75 | 35.5 | 60 | 51 | ||

| GX500 | 90 | 79 | 75 | 70 | 60 | 85 | ||

| GX600 | 90 | 139 | 60 | 97 | 45 | 134 | ||

Xinhai Mining provided a full mining industry chain service (EPC+M+O) project for a gold mine tailings cyanide removal project in Mongolia. In the material conveying stage, Xinhai Mining has customized two kinds of conveying equipment, the belt conveyor and the screw conveyor, for the project. Among them, the screw conveyor has good sealing performance and reliable operation, which is convenient for intermediate loading and unloading, and the conveying direction can be reversed or conveyed in opposite directions at the same time, which greatly improves the material conveying efficiency.