If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

High purity quartz(HPQ), plays a big role in many high-tech items. Think about chips in computers, solar cells that catch sunlight, thin glass threads for internet cables, and special lab glass. What makes HPQ stand out is how few tiny bits of junk, especially iron and aluminum, hide inside it. Even a speck of those can mess up how things work or break easily. That super-clean level matters a lot.

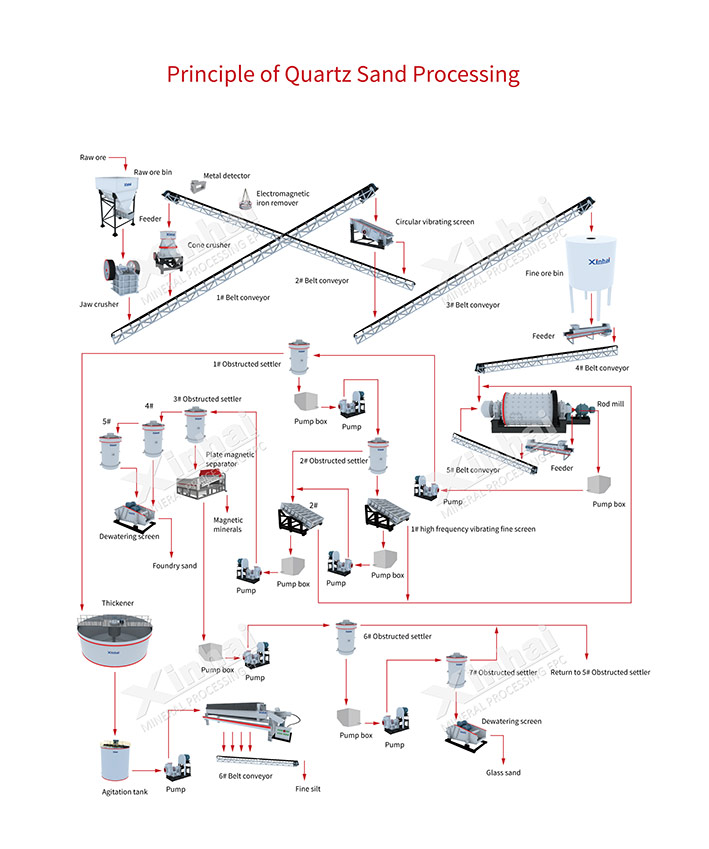

The production process of high-purity quartz sand involves multiple steps, each of which requires strict technical control to ensure the purity and quality of the final product. Workers watch every stage closely. This careful work sets HPQ apart from regular sand used in buildings or roads. It also explains why countries fight to control HPQ supplies.

Long ago, people started with their eyes and hands. A worker would pick up a big chunk of quartz rock. He’d look for dark spots or colorful streaks. If he saw any, he’d toss that piece away. Only clean-looking blocks stayed. Next, they broke those blocks. They used heavy jaw crushers that chomped like giant teeth. Then ball mills spun and ground the bits smaller. The noise was loud, dust flew everywhere. But iron from the steel machines rubbed off onto the quartz. So, extra steps later had to scrub that new iron away.

These old ways felt slow and tiring. Yet they taught everyone the first lessons. People learned how to spot bad pieces. They figured out ways to make rocks into powder. Honestly, it was messy, but it worked back then.

Once the quartz turned into gravel or sand, acid baths came next. Workers poured strong hydrochloric acid or sulfuric acid over the pile. The liquid soaked in and grabbed onto iron or aluminum stuck on the surface. Bubbles rose, colors changed, and junk floated out. But some impurities sat deep inside the crystal, like bugs frozen in amber. Acid couldn’t reach them easily.

The purification process of quartz sand is a key step to ensure the quality of high-purity quartz sand products. Old leaching helped, sure. Still, it left too many traces for today’s picky gadgets. Plants often ran the same batch through acid two or three times just to be safe.

Heat entered the picture to chase away what acid missed. Big ovens roared at 1000°C or higher. Quartz sat inside for hours. Hot air pushed organic gunk and some metals to the surface. There, they burned off or turned to gas. Workers later washed the cooled sand again. Energy bills soared. And deep impurities still laughed at the flames.

One factory I heard about in the 1980s used coal-fired kilns. Black smoke poured out daily. Neighbors complained. Purity barely hit 99.9%. That wouldn’t cut it now.

Today, machines do the looking. A conveyor belt carries raw quartz under bright lights. Lasers zap across. Infrared cameras snap pictures every millisecond. If a grain holds even 10 parts per million of iron, a puff of air blasts it into a reject bin. Magnetic rollers then pull away any iron-rich specks the eye can’t see. Froth flotation tanks follow. Chemicals make quartz float while feldspar sinks. Everything happens fast and clean.

Acid treatments grew up. Now, plants mix hydrochloric, hydrofluoric, and oxalic acids in exact ratios. Heated pressure vessels push the brew deep into crystal cracks. A single batch might cycle through four different tanks. Each tank targets a specific metal. Ion-exchange columns wait downstream. Resins grab stray ions like flypaper. Final rinse water tests cleaner than bottled spring water.

Ultra-high purity quartz sand requires extremely high purity and the lowest iron content. Its production process includes: those tough multi-acid dances. Result? Iron drops below 1 part per million.

New furnaces act like science labs. Computers control temperature to within 1 degree. Some run in vacuum. Others flood with chlorine gas to snatch fluorine-loving impurities. Quartz grains tumble slowly so every side gets equal heat. Sensors watch for color changes. If anything looks off, the system adjusts on the spot.

The production process of high-purity quartz sand is the key to ensuring the high quality and high purity of quartz glass. Modern ovens do double duty. They purge junk and round sharp particle edges. Smoother grains pack better in crucibles later. One Chinese producer shaved 15% off energy use by switching to inductive heating in 2022.

Old ways leaned on sweaty workers and simple tools. Purity bounced around. One day good, next day not. Lots of sand ended up in landfills. Plants needed huge crews. Acid spilled. Smoke choked the sky.

New lines hum quietly. Robots rule. Cameras never blink. Computers log every gram. Through precise raw material processing, advanced purification technology and strict quality control, we can effectively cope with the challenges brought by the depletion of crystal resources and promote the sustainable development of the quartz glass industry. Yield jumped from 50% to over 85% in many factories. Chemical use fell 30% because recycling loops catch spent acid. Air stays cleaner. Workers wear lab coats instead of dust masks.

Numbers tell the story. A traditional plant processing 100 tons of ore might ship 20 tons of HPQ. Modern ones ship 70 tons from the same pile. That gap decides who stays in business.

Xinhai Mining has extensive experience in quartz processing and has successfully undertaken dozens of quartz purification projects. Xinhai utilizes a variety of processing methods, including gravity separation, flotation, and acid leaching, to achieve quartz purity levels up to 99.999%. We can provide all the equipment for the entire production line and can also assist in designing your quartz beneficiation and purification process.

Our quartz sand processing plants are all intelligent plants, utilizing advanced digital twin technology for simplified management and production. We also offer EPC services for quartz processing. Please contact us if you require assistance!

1. What is the difference between ordinary high-purity quartz sand and ultra-high purity quartz sand?

Ultra-high purity quartz sand requires extremely high purity and the lowest iron content. Its production process includes: extra fussy steps. Ordinary sand stops earlier. Ultra keeps scrubbing until iron hides at one digit per million.

2. Why is chemical leaching important in high purity quartz processing?

The purification process of quartz sand is a key step to ensure the quality of high-purity quartz sand products. Acids grab metals that wreck chips or solar cells. Without leaching, gadgets fail fast.

3. What role does thermal treatment play in modern HPQ processing?

Heat kicks out stubborn bits acid misses. It also smooths grains. The production process of high-purity quartz sand is the key to ensuring the high quality and high purity of quartz glass. Smart ovens control gas and temperature perfectly. End result shines brighter under microscopes.