If you want to know more information (such as product/process price, etc.), please contact us 24-hour telephone

Since its establishment in 1997, Xinhai Mining has provided services to more than 2,000 mining projects across numerous countries and regions worldwide, continuously expanding its international market presence. The 1,200 t/d lead–fluorite project in Italy is not only Xinhai Mining’s first EPC project in the European market, but also represents a milestone as the 101st country in which the company has delivered overseas mining services.

(Xinhai Project Distribution Map)

The project covers a full range of services, including mineral processing testwork, engineering design, equipment supply, and installation guidance. Relying on stringent quality control standards, advanced process design, and a comprehensive service system, Xinhai successfully achieved all technical performance targets. This project demonstrates Xinhai’s capability to deliver mining services in developed European countries and marks a significant step forward in the company’s global development strategy.

The Sardinia lead–fluorite project in Italy focuses on the efficient separation of galena and fluorite. The designed processing capacity is 1,200 t/d, with a core grinding and flotation capacity of 900 t/d. The run-of-mine ore grades are 30–32% CaF₂ and 1–3% PbS.

Fluorite concentrate: 98.06% CaF₂, recovery 68.3%

Lead concentrate: 63.58% Pb, recovery 96.4%

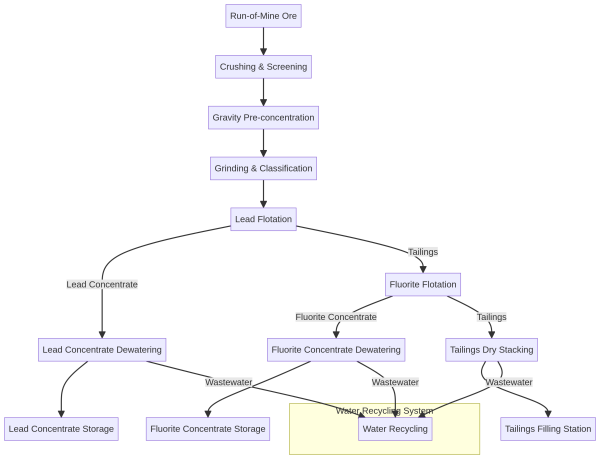

The process flowsheet was developed based on Xinhai Mining’s metallurgical test reports and further optimized using the company’s extensive experience in fluorite beneficiation projects. A fully integrated, closed-loop production line was established, consisting of:

Crushing & screening – gravity separation – desliming – grinding & classification – flotation – dewatering – dry tailings disposal

(Process Flow Diagram)

The crushing and screening system adopts a three-stage crushing process. The run-of-mine ore first undergoes primary crushing underground, then is hoisted to the surface via a vertical shaft, followed by secondary and tertiary crushing and screening. The final qualified product, 0–8 mm, is conveyed to the fine ore bin.

For externally sourced ore, material smaller than 200 mm is loaded into a dedicated ore bin and conveyed to the secondary crusher to ensure compatibility with downstream processing requirements.

The gravity separation system serves as a key pre-concentration stage. After crushing, low-grade fluorite ore is screened by a linear vibrating screen:

0–2 mm fraction: deslimed and sent directly to grinding

2–8 mm fraction: treated by jigging machines

Jig concentrates are dewatered and fed into grinding, while jig tailings are dewatered and sent to crushing or grinding, then conveyed to the backfilling station. High-grade fluorite ore is fed directly into the ball mill feed bin.

The grinding and classification circuit adopts a single-stage closed-circuit grinding process, producing slurry with 60% passing −200 mesh, providing high-quality flotation feed.

(Lead-Fluorite-Flotation)

The flotation system follows a “lead-first, fluorite-later” separation strategy. Lead flotation uses 1 rougher, 2 scavengers, and 2 cleaners. Fluorite flotation adopts 1 rougher, 1 scavenger, and 7 cleaning stages, with middlings from Cleaning I–IV subjected to regrinding.

Lead concentrate is thickened, filtered, and conveyed to the lead concentrate storage facility. Fluorite concentrate is thickened, filtered, stored, and periodically bagged for sale.

Tailings are treated using a dry stacking and backfilling system. All process water is recycled within the plant, achieving zero wastewater discharge and supporting green mine development.

(Italian customer inspection - hydrocyclone)

As Xinhai Mining’s first benchmark project in Europe, the Italian project faced stringent EU requirements. Xinhai successfully delivered the project through integrated industrial capabilities, strict quality control, and customized solutions.

The project strictly complies with EU CE certification, marking Xinhai Mining’s first successful CE-certified project. All equipment and safety systems meet EU requirements.

Heavy equipment and rotating parts are equipped with yellow safety guards. Electrical panels feature live-part protection and clear safety signage. Operating platforms and walkways comply with relevant safety load standards.

Motors from Siemens and ABB (IE3 efficiency class) and SKF bearings ensure efficient and reliable operation. All corrosion-prone surfaces use a three-layer coating system with a total thickness of 260 μm, compliant with ISO 12944 C4.

Core wear parts, including slurry pumps, hydrocyclone liners, and mill liners, use Xinhai’s proprietary wear-resistant rubber, significantly extending service life and reducing operating costs.

The plant structure adopts prefabricated steel portal frames and modular platforms, shortening construction time while improving sustainability and recyclability.

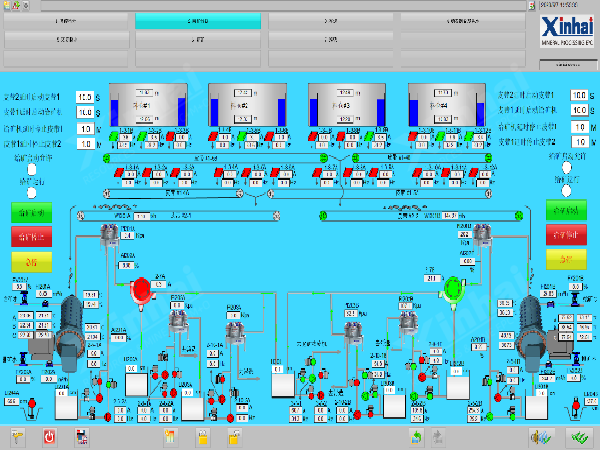

A fully integrated automation and instrumentation system covers crushing, grinding, flotation, dewatering, and reagent preparation.

- Interlocked start-up and shutdown for crushing and screening

- Automatic control of grinding feed rate, water addition, and hydrocyclone pressure

- Laser level meters and PID control for flotation pulp level and air flow

The control system is based on Siemens S7-1500 PLCs, with HMI software supporting real-time monitoring, data analysis, and reporting.

(Automation Control Interface)

The successful delivery of the Italian 1,200 t/d lead–fluorite project marks a key breakthrough in Xinhai Mining’s globalization strategy. Leveraging CE certification and EPC expertise, Xinhai has established a strong foundation for further expansion into the EU and European Economic Area.

The project showcases automated, green, and compliant mineral processing technologies, demonstrating the strength of China’s mining engineering services in the European market.

(Xinhai Mining factory)

The successful implementation of the 1,200 t/d lead–fluorite project in Sardinia, Italy, represents an important milestone in Xinhai Mining’s European market expansion. Building on this achievement, Xinhai will continue to strengthen technological innovation and integrated service capabilities, delivering efficient, sustainable, and high-quality mining engineering solutions worldwide.

If you are seeking a professional and reliable mining engineering partner or wish to learn more about customized mineral processing solutions, please feel free to contact Xinhai Mining.